2021 goal: cost-effective planning

Times have changed and unprecedented events turned our perception of normality upside-down. Almost everybody’s plans for the near future have been postponed or even changed significantly.

We at Instrumentation Technologies are conscious of and fully support the fact that budget optimization is now the priority for many companies and managers who wish to safeguard their assets. Businesses are targeting safe, low-risk investments that can bring cost-effective solutions in order to avoid unexpected expenses and budget increases.

On the other hand, this is also the moment to gain market competitiveness by choosing the right project partner that can ensure full reliability, with long-term experience and knowledge of providing lasting solutions.

On-time, on-budget, on-specs development

This kind of support has been successfully provided by Instrumentation Technologies many times over the years: our specialized team is more than familiar with satisfying conditions such as budget optimization and maximal product value. For several customers the creators and developers from Instrumentation Technologies and Red Pitaya have developed specific DAQ devices, entirely tailored to the customer’s requirements. With a dedicated team of engineers and other experts, Instrumentation Technologies can to deliver development projects on-time, on-budget and on-specs.

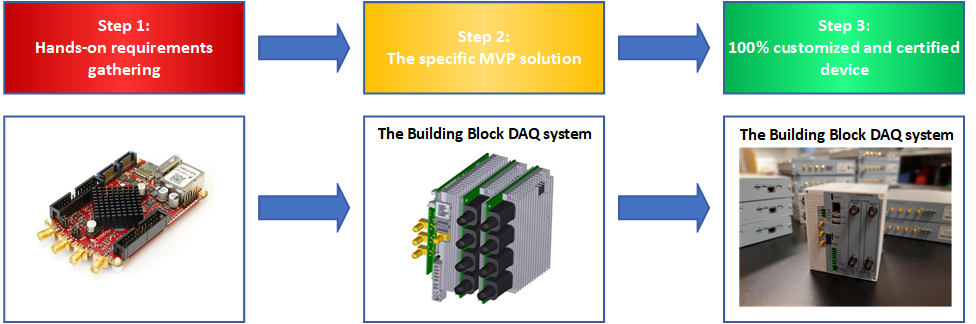

Every requirement derives from a unique situation, and every customer is looking for a specific solution, thus the process used to meet exclusive needs is a simple three-step strategy based on cooperation between our team of experts and the customer:

- Hands-on requirements gathering

Firstly, we provide a general-purpose Edge device with DAQ capabilities (Red Pitaya: https://www.redpitaya.com/), and together with the customer we analyze the specific needs to understand the actual challenge and provide hands-on feedback with regard to the possible solution. This direct approach allows us to expedite the gathering of exact project requirements.

- The specific MVP solution

Following the requirements gathered during step 1, our team of engineers designs the solution specific for the situation, both on the hardware and software side. The aim of this step is to define the extent of the Red Pitaya device enhancement: we will boost the unit’s performance in order to target the exact problem that the customer is facing.

- 100% customized and certified device

The result of this final step gives the best performing and cost optimized solution, meaning that the device provided to the customer is a fully tailor-made and certified product featuring enhanced analog and digital hardware performance, complete software control, with real-time processing capabilities and wired or wireless remote access (e.g. via Wi-Fi or Ethernet).

Our solution satisfies demanding user requirements for 100% customized applications in the industrial field: Instrumentation Technologies’ objective is to provide a device that evolves from a generic instrument, such as the Red Pitaya’s STEMlab and SIGNALlab, to an advanced industrial tool, adapted to specific needs.

The Building Block DAQ system

The customization is based on the DAQ Building Blocks system, designed to supply tailored solutions for demanding DAQ applications by using standardized components and drawing on years of experience. This approach allows us to avoid the usual drawbacks of systems developed from scratch: long and unpredictable R&D cycles, impacting the final budget; reliability issues with newly designed systems; possible problems with EMC certification, essential for equipment with wireless connectivity, operating in noisy electromagnetic environments and likely to cause or suffer from problems with RF interference.

Learn more about the Building Block DAQ system here.

One example of a company that trusted our three-step strategy and found the needed solution:

- A European Fortune 500 manufacturer of trains and railway infrastructure, looking for a solid, flexible, and ruggedized monitoring system to scan a large amount of specific rail equipment and observe the fast transients.

Conclusion

With our three-step approach, the customer gets a scaled and predictable offer, which eliminates large project deviations and unforeseen budget increases. Moreover, when planning effective budget allocation, it is essential to avoid indefinite and vague Time and Materials Contracts.

By fully understanding the challenges and requirements with regard to both parties, Instrumentation Technologies can provide a transparent project outline with best cost and effort estimation. Instead of an uncertain Time and Materials Contract, our customers get a precise and defined Fixed Price Agreement allowing them to avoid unpleasant surprises and stick to the planned budget allocation. Based on concluded projects we’ve learned that with our three-step approach customers see an 8% decrease in the overall development cost and 15% further reduction in the project duration. Instrumentation Technologies is committed to delivering the highest level of client satisfaction in high-reliability DAQ solutions. Our purpose is to match and exceed our customers’ expectations by providing DAQ solutions on-time, on-budget and on-specs.